With its mtu engines, Rolls-Royce Power Systems is quite literally propelling the yachting industry forward. But the company is no longer just an engine supplier – it delivers fully integrated solutions. Denise Kurtulus and Tobias Kohl explain the strategy to HANSA Yachts. By Anna Wroblewski

Rolls-Royce Power Systems is among the leading propulsion suppliers in the yacht industry. Under its mtu brand, the company powers numerous yachts from 25 metres in length – including those from renowned builders such as Azimut Benetti, Ferretti and Sanlorenzo. In the megayacht segment, Rolls-Royce also collaborates with shipyards like Lürssen.

One of the latest examples is the 30-metre “Azimut Grande 30M”, a highlight of the upcoming Cannes Yachting Festival 2025. Rolls-Royce has delivered the first fully integrated and highly efficient mtu pod propulsion systems for this new series to the Italian Azimut Benetti Group. Each yacht features two mtu 12V2000M96 engines, a new high-performance ZF 4900 pod drive, and the mtu NautIQ Blue Vision NG automation system, which – together with a ZF control system – monitors all powertrain functions. Several configurations are available, offering power outputs of up to 2,000 hp – making it the most powerful engine-pod combination currently available on the yacht market.

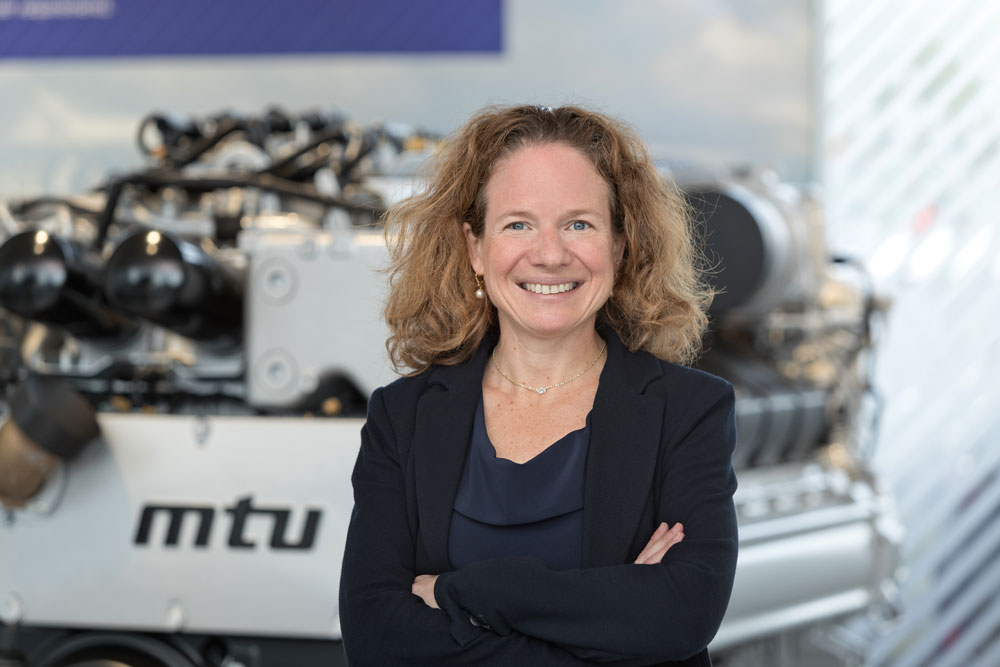

This propulsion setup represents one of the four strategic pillars in Rolls-Royce Power Systems’ current portfolio, as Denise Kurtulus (Senior Vice President Global Marine Business) and Tobias Kohl (Vice President Application Engineering Marine) explain in an interview with HANSA Yachts. We spoke with both about the latest developments and the trends shaping the future of marine propulsion.

Regulatory pressure to reduce emissions has driven major changes in the portfolio. Rolls-Royce no longer sees itself merely as an engine manufacturer, but as a holistic system provider. The goal: to optimise vessel performance from bridge to propeller, ensuring maximum efficiency and minimum emissions. Digital tools like mtu NautIQ Foresight and integrated bridge solutions play a key role in this approach.

The problem is the fuel, not the engine

As Denise Kurtulus explains, the combustion engine remains the first pillar of this strategy. Even 150 years after its invention, it is still regarded as one of the most efficient technologies – despite growing demands for emissions reduction and the ongoing energy transition. “We do not see the combustion engine as the problem, but rather the fuel,” says Kurtulus.

The second pillar is hybridisation. What was once viewed at Rolls-Royce as a transitional technology has now become a well-established solution for reducing emissions, she adds.

The third pillar focuses on system solutions – the so-called “bridge-to-propeller” approach. Rolls-Royce has made significant investments in this area in recent years, not only in R&D but also through strategic acquisitions. One example is the acquisition of bridge and automation specialist Team Italia, which now enables Rolls-Royce to offer integrated bridge solutions. Similar to an aircraft cockpit, the aim is to manage all critical onboard data via the bridge – improving both efficiency and safety.

The fourth pillar is service. Here, Rolls-Royce aims to provide everything from a single source and further optimise vessel operations through data-driven support. The focus is on delivering the best possible service as onboard systems become increasingly complex.

Is the combustion engine obsolete?

At a time when fossil fuels are increasingly viewed critically, continuing to rely on combustion engines may seem anachronistic to some. For Rolls-Royce, however, it still makes sense. The company continues to work on improving existing technologies – for example, through exhaust after-treatment, which significantly reduces emissions. The use of HVO (Hydrotreated Vegetable Oil) can reduce CO₂ emissions by up to 90%. “We don’t need to wait until methanol is widely available. We can already achieve significant emissions reductions today,” says Kurtulus.

On the subject of methanol, she touches on an important point. Rolls-Royce Power Systems was one of the first companies to commit to methanol and has invested heavily in research and development in this area. Methanol is still seen as a fuel of the future, even though political and regulatory frameworks have slowed progress. “It’s unfortunate that regulation and politics have not kept pace with the industry’s expectations,” says Kurtulus. “We were ready, we invested, but without infrastructure and green methanol, scaling up in the industry is pointless. I’ve been in this industry for 20 years, and I’ve never experienced such momentum, with operators, shipyards and suppliers worldwide so united: methanol is the right path. Unfortunately, the necessary support is still lacking.”

Rolls-Royce will therefore not withdraw from this area but will proceed more cautiously with its investments. Without incentives, infrastructure, and available green methanol, converting ships makes little sense. The company remains committed to the topic but intends to stay in technology development mode for the time being, explains Denise Kurtulus.

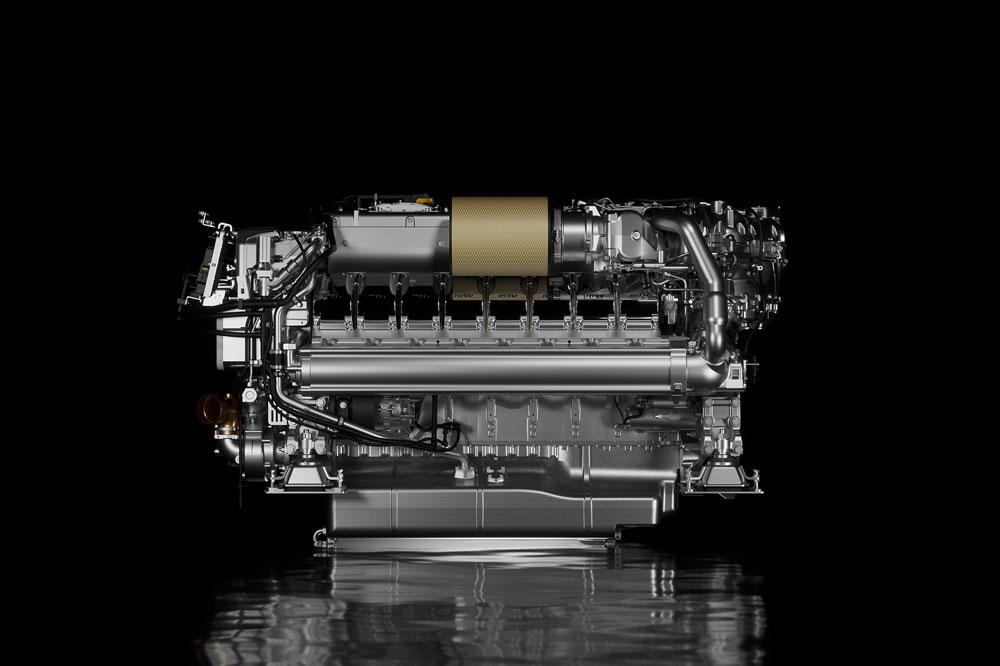

Against this backdrop, Rolls-Royce is also reassessing its combustion engine portfolio. A new, more powerful model in the 2000 series was recently introduced. The 12-cylinder version of the mtu 12V2000 M96Z engine will be launched from 2026. By further developing various components, Rolls-Royce has increased power output to 1,634 W (2,222 hp) from 1,472 W (2,002 hp). Power density has been raised to a new level, with only minor changes in weight and dimensions compared to the previous 12V 2000 M96X model. All large engines are now IMO Tier III capable.

“We continue to see the combustion engine at the heart of our approach – complemented by batteries, electrification, hybridisation. But also by automation to better utilise data and to support the crew on the bridge,” summarises Denise Kurtulus.

More efficiency, more space

Although combustion engines remain at the centre, a new trend for diesel electric systems is emerging, as Tobias Kohl adds. Particularly in the Northern European shipyard market, there is a move away from traditional large diesel engines towards variable-speed platforms. These allow significantly more power to be extracted from an engine. “Traditional systems with 50 or 60 Hertz do not allow the engine to reach its full potential because it cannot operate at higher speeds. With variable-speed drives, we extract considerably more energy from the same engine,” says Kohl.

Thanks to frequency converters, engines can be operated more efficiently. “There’s no need to run large engines at partial load; smaller engines can be used at optimal operating points. This provides greater efficiency and flexibility.” Here, the term “single deck engine room”, popular in the megayacht industry, also comes into play.. Variable-speed gensets require significantly less space, which in turn creates more room for cabins. “More power-dense engines create more living space for owners on board,” says Kohl.

Another important lever for improving efficiency, according to Kohl, is waste heat recovery. The heat generated by combustion engines can be used in a variety of ways, for example for heating, hot water or cooling, with air conditioning being one of the largest energy consumers on board.

A project combining new technologies

Due to confidentiality, Kurtulus and Kohl cannot speak about specific yachts where these integrated propulsion solutions are already in use. However, they do report that such systems are already in operation on several hybrid-electric ferries operated by Liberty Lines in southern Italy. These vessels are equipped with the complete Rolls-Royce hybrid system – including the NautIQ Foresight automation solution, which allows crews to monitor fuel consumption and operations and centrally manage all operating data.

A similar hybrid system with Series 4000 mtu engines, will be installed on a 76-metre Turquoise megayacht, which is due to enter service end of 2026.

In line with the “bridge-to-propeller” strategy, Rolls-Royce has also pod systems in its portfolio. These propeller solutions with integrated gearboxes are developed in cooperation with ZF. However, the complete integration, including calculations for vibration and the mechanical validation of the entire system, is the sole responsibility of Rolls-Royce.

“We have just completed testing of this fully integrated system. Naturally, efficiency always depends on the vessel’s design, but we were able to achieve efficiency gains of up to 20% through this integrated solution,” explains Kurtulus, revealing that a first Azimut yacht with the pod system will be on display in Cannes in September.

Rolls-Royce Power Systems is thus positioning itself as a system provider offering complete solutions. This not only helps improve efficiency but also reduces the workload for shipyards. When Rolls-Royce supplies a complete system, this saves shipyards valuable time both in development and construction.

As Denise Kurtulus concludes, Rolls-Royce aims to offer a kind of modular system for different yacht sizes from which shipyards and owners’ representatives can choose. “This modular system includes gensets, automation and digitalisation solutions, battery systems, and hopefully soon methanol engines. In this, we act like an energy consultant. After all, a ship is nothing more than a floating microgrid that requires many software solutions to manage energy efficiently.”