For decades, Geislinger has been supplying couplings and drive shafts for superyachts. In this interview, Torsten Philipp explains which trends are currently shaping the yacht market, how Geislinger is responding to new demands – and why yachts, in particular, are serving as drivers of innovation.

HANSA Yachts: What products or solutions does Geislinger offer for the yacht sector?

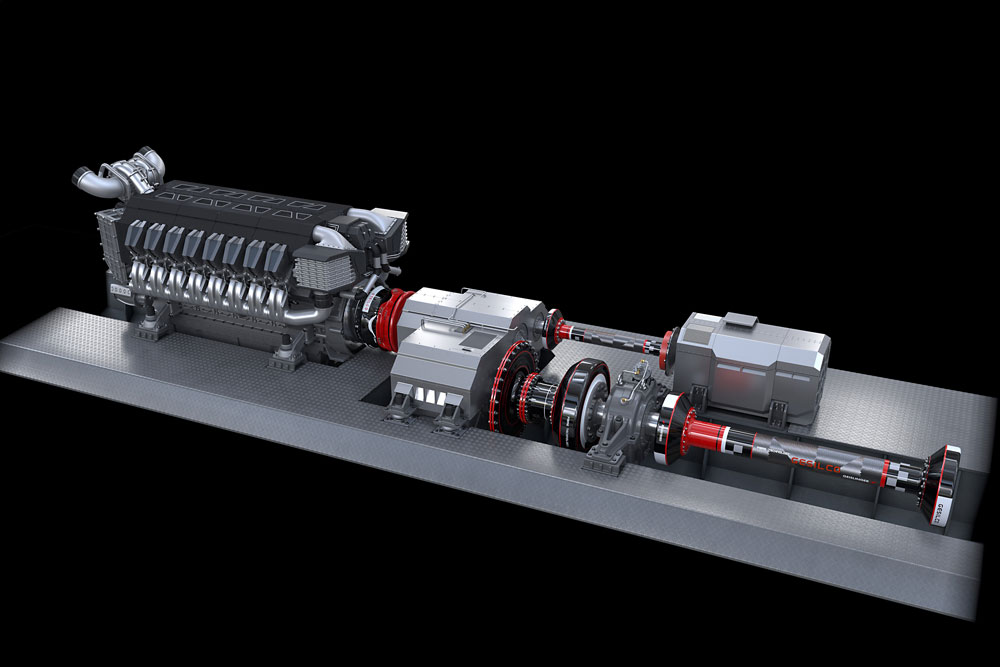

Torsten Philipp: In the yacht market, we’ve been supplying proven products for many years, such as flexible couplings made from steel and composite materials. These are typically installed between the engine and the gearbox, or between the engine and the electric machine. Our portfolio also includes composite drive shafts to the propeller. – these are our core propulsion products, which we’ve been developing and manufacturing in-house. With expertise in composite products for over 25 years.

Around a year ago, we expanded our portfolio to include a fully electric drivetrain all-electric propulsion systems. In cooperation with our partner AVL, we now offer a complete customized solution – including the electric machine and inverter. This marks our transition from a component supplier to a system provider.

Which yacht sizes does Geislinger target with its portfolio?

Torsten Philipp: Our roots lie in the segment of very large yachts, those over 100 metres in length. That’s where our journey in the yacht market began many years ago. We’re still strongly represented in this segment and hold a significant market share.

At the moment, we’re increasingly tapping into smaller segments, down to around 80 metres in length. For fully electric yachts, we cover propulsion power ranges from 1.2 to 1.5 MW – suitable for yachts of up to around 50 metres.

Which trends are currently having the greatest impact on the Geislinger portfolio – and what requirements arise as a result?

Torsten Philipp: A central topic is the hybridisation of propulsion systems with various operating modes. In the past, combustion engines could be optimised for a specific operating point – such as full load or continuous operation. With hybrid systems, engineers now have to consider how the load is distributed between the electric machine and the combustion engine: when is each activated or disengaged, how long does the system remain in each mode? The complexity of propulsion systems has increased significantly.

Another trend strongly influencing our development is acoustics. Particularly in the yacht sector, there’s a growing demand to reduce noise and vibrations to an absolute minimum – especially on overpowered yachts where comfort is a priority. This places high demands on ship design, and especially on the drivetrain. Our role is to ensure that sound doesn’t propagate through the powertrain – through the use of acoustically optimized couplings and shafts. The extensive acoustic expertise we’ve built up over the years has been heavily shaped by the yacht segment. Alongside the navy, it’s our strongest driver of innovation in this field.

I often compare it to the technology funnel in the automotive industry: high-end segments – like the Mercedes S-Class – are where new technologies are developed before they trickle down to mass production. It’s similar in yacht building, particularly in the luxury sector. This is where advanced propulsion solutions are created, with all their challenges – and later transferred to other vessel types.

Another major driver is lightweight construction. For a long time, lightweight design was seen as contradictory to noise insulation, since sound-dampening components tended to be bulky and heavy. We’ve succeeded in uniting both requirements – acoustic performance and weight reduction. This offers major benefits: the lighter the drivetrain, the more efficient the operation and the lower the fuel consumption. In hybrid systems especially, this helps offset the additional battery weight.

Is there a current yacht project that particularly showcases the strengths of Geislinger’s couplings?

Torsten Philipp: I’d love to mention a specific project – but yacht projects are typically subject to the strictest confidentiality. What I can say is this: there are only a few shipyards in Europe – such as in Germany, France or the Netherlands – that specialise in large yachts. And nearly every major vessel that leaves those yards is equipped with Geislinger components.

One example I can share comes from the ferry sector: we recently equipped the fully electric 130-metre-long RoPax ferry “China Zorrilla”, built by Incat Tasmania. The technical requirements were similar to those in the yacht segment. For this project, we supplied carbon-fibre drive shafts, flexible couplings and hubs for the propulsion system.

Where do you see trends in coupling technology for the yacht sector? What solutions is Geislinger currently working on?

Torsten Philipp: As already mentioned, we see the main trends in lightweight construction and acoustics. A third and increasingly important area is our expertise in electric propulsion. As a company rooted in mechanical engineering, we now need a far deeper understanding of what’s happening on the electrical side – for example with insulation, short-circuit resistance, or interface design.

It’s about identifying the skills we need to develop in order to integrate our products into an electric onboard network. This transformation is a major focus for us.

In the field of acoustics, we’re investing heavily in predictive accuracy. Around ten years ago, we built one of the world’s largest acoustic drivetrain test benches. Now, we want to further improve simulation capabilities together with our partners. We have this expertise in-house – which shows how important this topic is for us. During coordination phases between engine manufacturers, shipyards and acoustic experts, reliable predictions are essential – both for the hull and the propulsion system.

And that’s exactly what we can do: deliver high-quality forecasts during the simulation phase – not just later on the test bench. This enables us to perform a factory acceptance test (FAT) without needing numerous prototypes. After all, yacht building involves bespoke, one-off designs – there’s neither time nor budget for repeated hardware iterations.

We continue to develop this simulation expertise internally but also regularly collaborate with leading universities and acoustics institutes. The same applies to our material expertise – whether in composites, elastomers or steel. Here too, we work closely with specialists. And that’s exactly what our customers expect from us.

Interview by Anna Wroblewski